With the basic knowledge of business process, we start learning some specific business process like last week’s Order to cash and this week’s procure to pay. From my understanding, these two topics are actually talking about the same event but from two sides. O2C is more from a supplier’s side talking about the process from getting an order from a customer to getting the cash for the payment, while P2P is more from a buyer’s side talking about the process from getting purchase requisition from internal customer to finance department actually pay to suppliers.

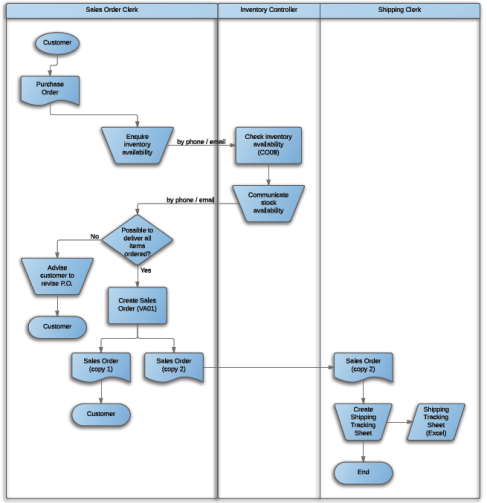

As usual, the first part of the seminar was in financial trading room. The activity is about order to cash process. We were required to correct the given flow chart of a O2C process.

There are many different ways to improve this flow chart. There are some detailed process wasn’t shown in this chart like credit check and packing and picking up for warehouse. Besides that, the flow could be more efficient as well. For example the process that sales order clerk needs to ask the inventory controller to check the availability of the inventory customers required. This process is very redundant due to the whole enquiry and waiting information time. Company might lose customers because of this inefficiency. To improve it, we can simply use SAP system, hence sales clerk can check the availability of the product himself directly when he gets the enquiry from customers.

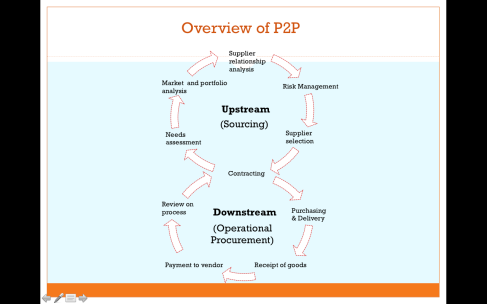

In the second part of the seminar, our group sunshine did the presentation of the topic Procure to pay(P2P).

We took the advice from last group’s presentation, we started with the overview of the topic P2P and a mini game to make everyone understand the rough idea. After preparing students with some basic idea, we get into the details of the procurement processes. However, from our own experience in last seminar, we noticed that in their mini-game, they made one group to play one role, resulting that some students didn’t get a chance to touch the game. So we decide to conduct the game within one group, hence everyone would play one role. In this case, they will have an experience in the game and have a better understanding of the topic.

For the knowledge itself involved in this topic looks quite straight forward, however it’s not. After James’ consultation, we understand that the business process here can be divided into two main parts– upstream activities and downstream activities. Upstream is also known as sourcing, while downstream is known as operational procurement. From my understanding, sourcing is actually doing all the preparations for the operational procurement. Hence upstream activities would involve a lot of work in understanding internal customer, vendor, market…While downstream would focus more on the procurement itself.

All the purchases can be classified into new purchase and recurring purchase. New purchase refers to the purchase requires new vendor selection and recurring purchase refers to the purchase that the company is still in a contract with a specific vendor, hence they don’t have to do vendor selection.

Upstream Process

I was responsible for upstream process, so I will talk more about upstream process here.

Needs assessment is a very important process before procurement organization making decisions. Since their purchase should be based on the requirements of their internal customers. They need to fully understand their requirements to avoid understatement of needs or overstatement of needs or even misunderstanding of needs. Because all of them will result money waste in the end. While this is exactly what we are trying to avoid. Hence build a sound relationship with internal customer is important, not only for the exact requirement, also for avoiding the case that some department might skip the procurement department to sign contract with vendors.

Market analysis is a process that the procurement org collect and analyze the data from supply market to know more about the investment to be made risks involved. They will need to go through -Specify product or service -Determine cost structure -Research suppliers -Identify key market indicators

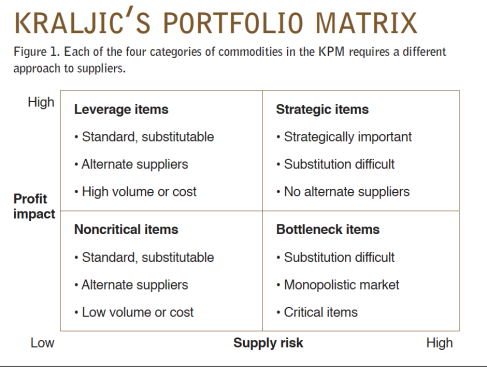

Portfolio analysis is a process of purchase classification based on supply risk and profit impact.

- Supply risk is high when the item is a scarce raw material, when its availability could be affected by government instability or natural disasters, when delivery logistics are difficult and could easily be disrupted, or when there are few suppliers.

- Profit impact is high when the item adds significant value to the organization’s output. This could be because it makes up a high proportion of the output (for example, raw fruit for a fruit juice maker) or because it has a high impact on quality (for example, the cloth used by a high-end clothing manufacturer).

There is a way to to the classification in a matrix called as The Kraljic’s Portfolio matrix. This is very helpful in portfolio analysis.

Supplier relationship analysis:

Understand the mutual relationship (Which type of the relationship can best fit the requirements. and how do supplier perceive the customer). For example when you are trying to find a partner, would you want the supplier company to see you as a long-term valuable respectable partner or just a small unimportant company. It helps the procurement org. the manage the relationship. to decide what strategy to choose.

Risk management is very straight forward. It includes,

| • Risk=Uncertainty of an outcome • Identify risks • Assess the importance of risks • Control the risks(Minimize or eliminate the risks) • Deal risks quickly and effectively |

||

Vendor selection is the process that you need to choose a vendor based on all the information you get through RFP or RFQ and all the analysis done before. To make the decision, they need to go through these steps

RFP is very important since it brings the structure to the procurement decision and is meant to allow the risks and benefits to be identical clearly upfront. |

Downstream Process

Downstream process includes five steps, contracting, purchasing and delivery, receipt of goods, payment to vendor and review on process(reflection of the procurement decision, any improvements based on current process). From the studying of the business process and the mini-game, we want to show to the students that there are many problems in the manual process like too many documents, inefficiency in the process, misunderstanding between departments, difficulties in monitoring vendor selection process(bribery) and the manual 3-way match checking.

HOW CAN SAP HELP?

- Facilitate communication (eliminate misunderstanding)

- Automation(increase efficiency)

- Control (monitoring vendor selection process)